Cotton, one of the most widely used natural fibers, undergoes a series of processes before it reaches its final form. Understanding how to process raw cotton can shed light on its benefits. We also look at why buying cotton in bulk from CPG Marketplace can be a cost-effective choice.

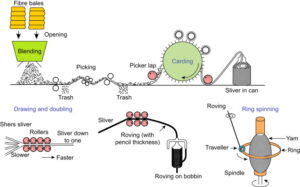

The process of transforming raw cotton into usable fabric involves several stages. First, the harvested cotton is ginned to remove seeds and impurities. This step ensures that only the purest fibers are retained for further processing. Next, the cleaned cotton fibers are carded to align them in a parallel arrangement, making them ready for spinning into yarn.

Spinning is a crucial step where the carded fibers are twisted together to form continuous strands of yarn. This yarn can then be woven or knitted into various fabrics or used for other applications such as thread production.

Discover the benefits of how to process raw cotton and its versatile applications. As leading wholesale suppliers we provide high-quality raw cotton for various industries. Explore our wide range of products and unlock the potential of this natural fiber. Contact us today for all your raw cotton needs.

Process Raw cotton

Cotton goes through several stages of processing before it’s ready to be used in various products. Here’s an overview:

- Planting and Harvesting: Cotton is a natural fiber that comes from the cotton plant. It’s cultivated in warm climates worldwide. When the cotton bolls mature, they are picked either by hand or machine.

- Ginning: After harvesting, the cotton fibers are separated from the seeds through a process called ginning. The cotton gin removes the seeds, leaving behind the raw cotton fiber.

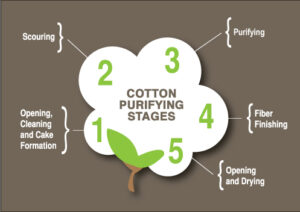

- Cleaning: Once separated, the cotton fibers still have impurities like dirt, leaf parts, and other debris. They go through cleaning processes, which can involve various machines and techniques to remove these impurities. This process helps prepare the cotton for spinning.

- Carding: The cleaned cotton fibers then go through carding, where they are pulled and straightened. Carding aligns the fibers to prepare them for spinning into yarn. It also further removes any remaining impurities.

- Spinning: The carded fibers are spun into yarn through machines that twist and draw the fibers together. This process creates strong, continuous threads of cotton yarn.

- Weaving or Knitting: The cotton yarn is then used to create fabric. In weaving, the yarn is crisscrossed on a loom to form the fabric. In knitting, the yarn is looped together to create the fabric.

- Finishing: After the fabric is made, it undergoes finishing processes such as bleaching, dyeing, printing, and sometimes additional treatments to enhance its properties, like softening or adding wrinkle resistance.

- Manufacturing: Finally, the finished cotton fabric is used in various industries to create a wide array of products, including clothing, household linens, medical supplies, and more.

process raw cotton

Benefits of cotton

One of the key benefits of raw cotton lies in its natural properties. Cotton is breathable, soft, and hypoallergenic, making it ideal for clothing and bedding products. It also has excellent moisture absorption capabilities, keeping you cool and comfortable even in hot weather.

Buying cotton in bulk from CPG Marketplace offers several advantages. Firstly, purchasing in large quantities allows you to take advantage of wholesale prices, ensuring cost savings for your business or personal needs. Additionally, CPG Marketplace provides a wide range of options when it comes to sourcing cheap cotton without compromising on quality.

In conclusion, understanding how to process raw cotton highlights its numerous benefits as a versatile material. Whether you’re looking to create clothing items or other textile products, buying cotton in bulk from CPG Marketplace ensures affordability without compromising on quality or sustainability.